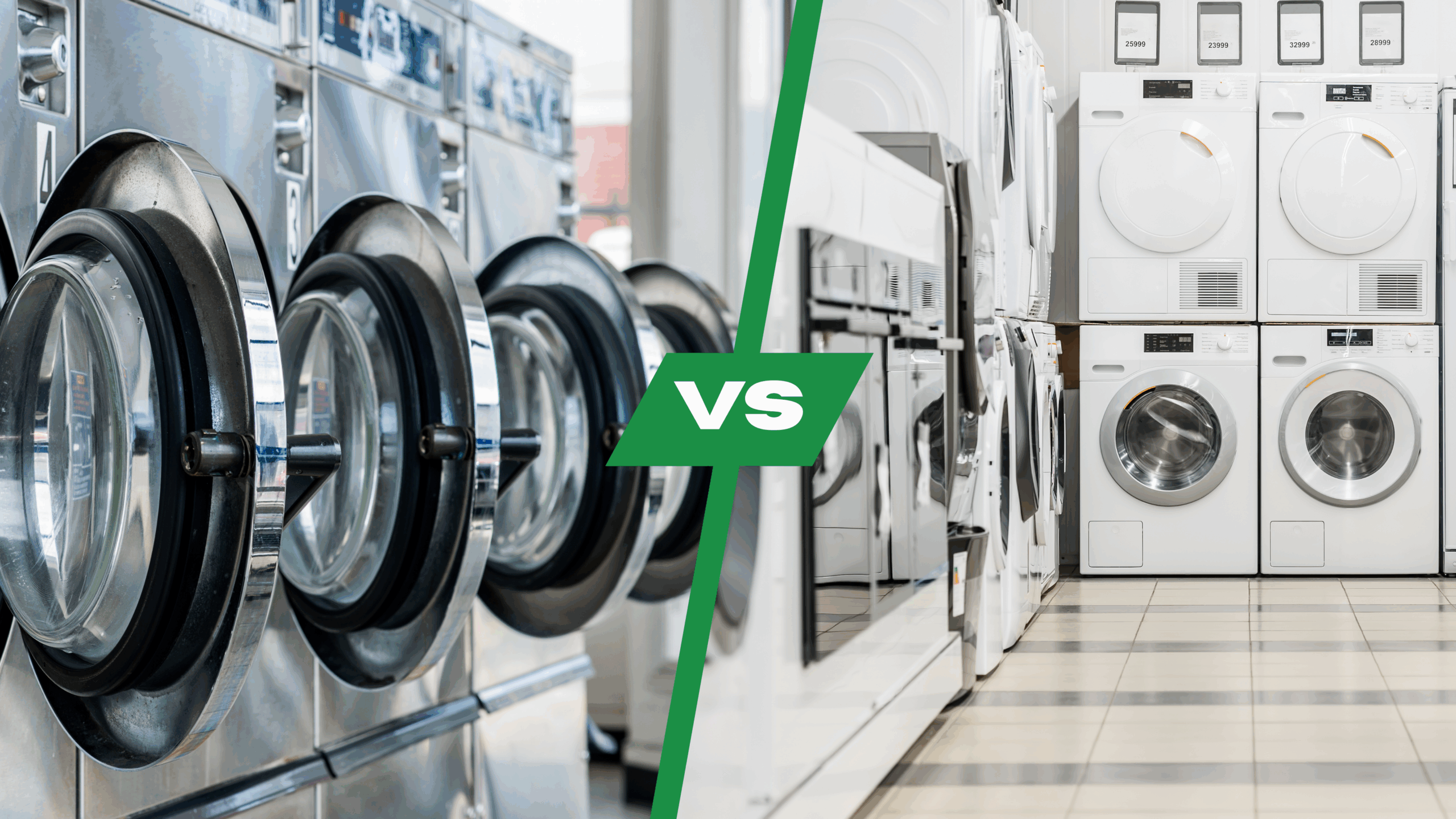

Many people believe that industrial laundry is simply about using machines with higher capacity than regular laundromats. There are significant differences between industrial laundry and conventional laundry services—from technology and treatment processes to hygiene standards and scale of operations. For organizations like hospitals, hotels, restaurants, spas, or manufacturing plants, where tons of linen need to be handled daily with strict delivery schedules, relying on a typical laundry service is not feasible.

So, how does industrial laundry differ from regular laundry? Why are more and more businesses choosing this model? Let’s explore in detail below to better understand and choose the solution that best fits your individual or business needs.

1. Differences in scale and target audience

1.1 Scale

To handle large volumes of linen daily, industrial laundry service providers must invest heavily in infrastructure, particularly in large-scale laundry facilities. These factories typically span thousands of square meters and are specially designed with dedicated functional areas such as the receiving zone, sorting area, and delivery zone. Each area is organized scientifically to ensure a closed-loop, continuous workflow, minimizing cross-contamination and optimizing operational efficiency.

Along with spacious layouts, these facilities are equipped with a full range of modern industrial machines, including high-capacity washers, industrial dryers, flatwork ironers, pressing tables, and support systems like hot water supply, wastewater treatment, and disinfection units. The entire system is highly automated to ensure the ability to process hundreds to thousands of kilograms of fabric daily, while maintaining consistent quality and saving time.

In contrast, traditional laundry services, usually small shops or household laundry facilities, only need a space of a few dozen square meters, equipped with domestic or semi-industrial washing machines and dryers, depending on the investment capital. Due to their small scale and limited machinery, these shops can only handle a modest amount of laundry per day, unable to meet large, urgent, or specific requests.

1.2 Customers/Partners

Due to the nature of operating on a large scale, industrial laundry service providers primarily serve businesses, organizations, and facilities with high-volume laundry needs daily. Typical customer groups include:

-

Hospitals and medical facilities require the laundering of large quantities of bedsheets, towels, patient clothing, medical uniforms, surgical fabrics, and various types of antibacterial textiles.

-

Hotels, resorts, and restaurants need clean and well-maintained linens such as bedsheets, pillowcases, bath towels, napkins, bathrobes, and curtains.

-

Spas, gyms, and beauty clinics frequently use body towels, face towels, robes, and floor mats, requiring regular and hygienic laundry service.

-

Factories and manufacturing plants: handling heavily soiled items like worker uniforms, oil-stained rags, and anti-static technical fabrics that require specialized treatment.

In contrast, conventional laundry services mainly cater to individuals or households with smaller and less frequent laundry needs, such as clothing, bedding, or curtains. These customers typically have fewer requirements regarding hygiene standards or delivery schedules, making traditional laundry services more suitable in terms of scale and flexibility.

2. Differences in machinery and technology

One of the most notable differences between industrial laundry and conventional laundry lies in the machinery and technology used. To ensure effective cleaning, time efficiency, and the ability to process large volumes of linens daily, industrial laundry providers must invest in specialized, high-capacity equipment with integrated automation features. In our article “Everything You Need to Know About Industrial Laundry” Green Laundry has listed the essential machines used in the process—readers can click the link to learn more.

Meanwhile, conventional laundry services only use small-capacity, manually operated, residential or semi-industrial washing machines and dryers that are not capable of continuous processing or meeting specific requirements. This equipment is only suitable for small, infrequent washing needs and does not require strict disinfection or quality control.

3. Differences in washing processes and standards

Unlike conventional laundry, industrial laundry services are operated through a closed-loop process, strictly standardized from intake to delivery to ensure cleaning effectiveness, hygiene safety, and consistent quality. Every step is systematically executed with the support of specialized machinery and fabric-specific detergents tailored to the type of fabric and its intended use.

A standard industrial laundry process typically includes the following key stages:

-

Fabric Sorting: Immediately after intake, all textiles are carefully sorted based on factors such as material (cotton, polyester, technical fabric…), color, level of soiling, and usage (bed sheets, uniforms, towels, medical fabrics, etc.). Proper sorting allows for the selection of the right washing cycle and chemicals, minimizing damage and preserving fabric quality.

-

Washing: After sorting, the textiles are washed with specialized detergents and disinfectants, dosed precisely based on fabric type and contamination level. The chemicals used in industrial laundry are usually eco-friendly, non-irritating, and meet safety standards.

-

Rinsing & Extracting: After washing, the textiles go through multiple rinsing cycles to thoroughly remove any detergent residue. Industrial extractors are used to remove most of the water before the drying phase, helping to save both time and energy.

-

Drying & Packing: Once rinsing and extraction are complete, fabrics are transferred to industrial dryers for fast drying. Depending on the item, they may then be ironed using a flatwork ironer or pressing table. Finally, they are neatly folded, packed with care, and prepared for delivery.

-

Delivery: Clean laundry is returned on time, as committed.

In contrast, conventional laundry services usually involve just basic steps such as washing, drying, and folding. Fabric sorting is often minimal, as regular household textiles don’t vary greatly, and stains are typically common and do not require specialized cleaning or disinfection processes.

With all this information, Green Laundry hopes to provide readers with a clearer understanding of industrial laundry services. More importantly, we aim to help you distinguish between industrial and conventional laundry, so you can make the right decision based on your specific needs.

Green Laundry – the leading company in providing quality and professional laundry solutions in Vietnam

Email: greenlaundry@giatuixanh.com

Phone: 028 36 222 180

Address: Lot A57/II-Lot 58/II, Road No. 2D, Vinh Loc Industrial Park, Binh Tan Ward, Ho Chi Minh City.