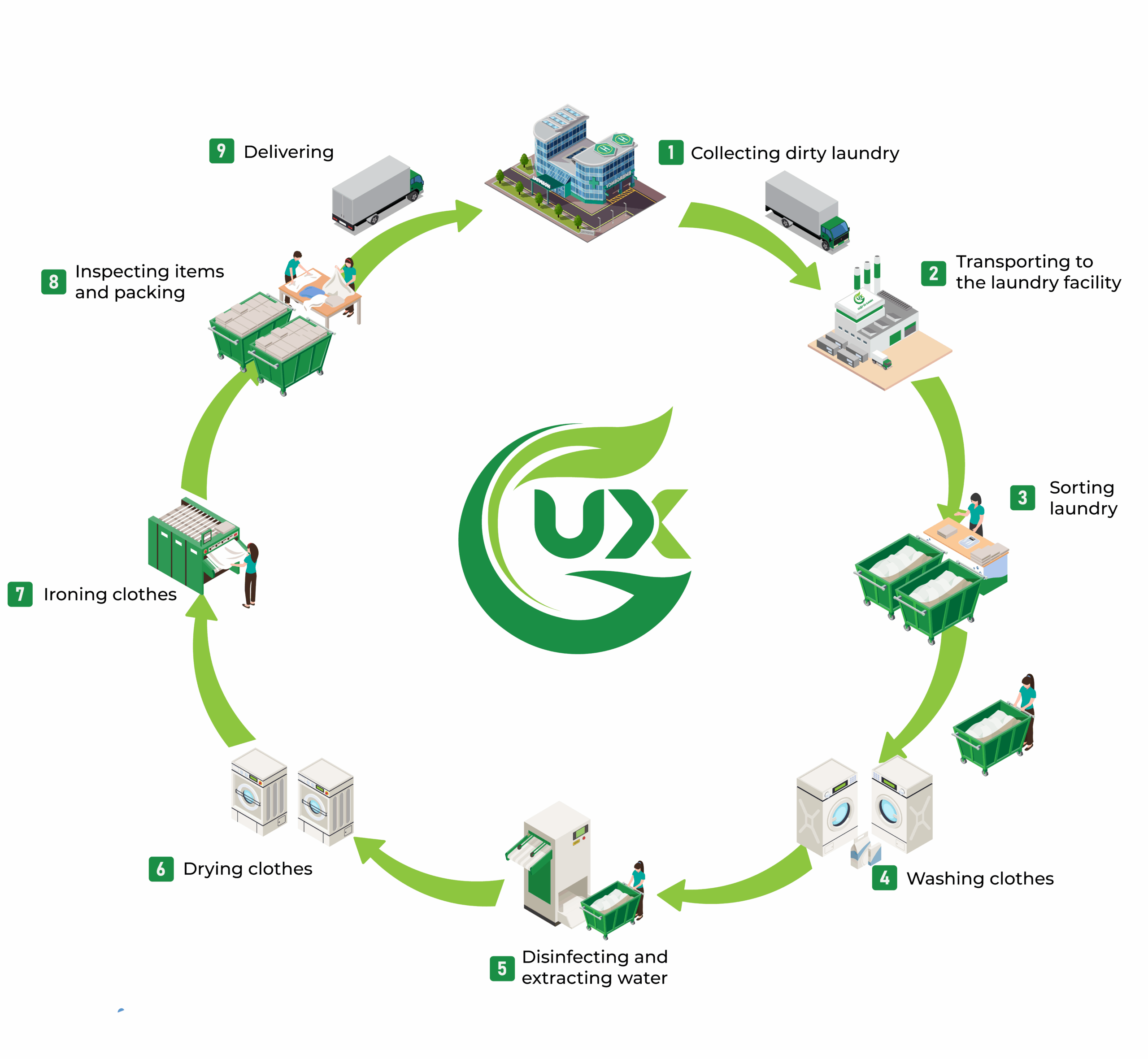

In the field of industrial laundry, the process is the decisive factor directly affecting the final product quality. Serving large-scale clients such as hospitals, hotels, factories, and spas requires absolute cleanliness, safety, and on-time delivery. Green Laundry has developed a closed-loop 9-step standardized laundry process, utilizing modern machinery and a strict quality control system to meet even the most demanding customer requirements.

1. Collecting dirty laundry

The collection stage is the crucial first step in Green Laundry’s laundry process. Our staff follow fixed daily routes or collect laundry according to the partner’s scheduled appointments. This ensures that linens are received on time, avoiding any disruption to hospital, hotel, or factory operations.

All items are packed and stored in sealed containers or specialized bags upon receipt, with initial sorting by category performed right at the collection point to prevent cross-contamination.

2. Transporting to the laundry facility

Laundry is transported to Green Laundry’s facility using dedicated vehicles. Upon arrival, we apply an intake and inventory check process to avoid any loss or mix-up.

Green Laundry guarantees that separate vehicles are used exclusively for soiled item, no clean and dirty laundry is ever transported together, ensuring all fabrics remain in the safest condition before entering the main washing stage.

3. Sorting laundry

Sorting is considered one of the most critical steps, directly influencing washing effectiveness and fabric durability. Immediately upon intake, all textiles are carefully sorted based on color, fabric type, soil level, and intended use such as towels, bedsheets, uniforms, curtains, or medical textiles.

Accurate sorting allows us to select the right washing program, water temperature, and specialized detergents for each category. This not only ensures optimal cleanliness but also prevents fading, shrinking, deformation, or fiber damage during processing. For medical or high-tech fabrics, extra caution is taken to meet hygiene standards and preserve their specialized properties.

4. Washing clothes

After sorting, all laundry is loaded into high-capacity industrial washing machines. Each batch is programmed with a customized cycle based on the fabric category identified in the previous step.

Green Laundry uses certified industrial detergents that are safe, eco-friendly, and dermatologically tested. Chemicals are precisely dosed according to fabric weight and type, effectively removing stains, grease, and bacteria while preserving softness, color, and fiber structure.

5. Disinfecting and extracting water

For healthcare partners where the highest hygiene standards are required disinfection is a mandatory stage. After washing, all fabrics undergo sterilization using high-pressure steam or specialized disinfectant solutions, eliminating all remaining bacteria, viruses, and pathogens on the textile surface.

The laundry is then transferred to industrial water extractors, which can remove 70–80% of moisture in a short time. This reduces drying time and mechanical stress on fibers, helping fabrics maintain durability without shrinking or distortion even after repeated cycles.

This specialized treatment ensures textiles meet absolute disinfection standards while maintaining long-lasting quality.

6. Drying clothes

After water extraction, fabrics are loaded into high-capacity industrial dryers. The entire drying process is precisely programmed and strictly monitored, with temperature settings adjusted according to fabric type and thickness for optimal results.

Thanks to specialized drying technology, finished textiles retain natural softness without shrinking, fraying, or warping, while eliminating residual moisture to prevent bacteria and mold growth.

7. Ironing clothes

During the finishing stage, Green Laundry applies different ironing methods depending on the textile type to achieve the highest level of presentation. Large fabrics such as bed sheets, tablecloths, and curtains are processed using industrial flatwork ironers with stable heat and fast throughput, leaving a smooth and professional finish.

For shirts, uniforms, or garments requiring precise presentation, professional pressing tables are used to create sharp creases and maintain proper garment shape.

Ironing not only ensures textiles are neat, smooth, and ready for immediate use but also enhances customer experience in professional environments such as hospitals, hotels, restaurants, and premium service facilities.

8. Inspecting items and packing

Once washing, drying, and ironing are completed, every item goes through a final quality inspection. Green Laundry’s QC team checks each piece to ensure no stains, frays, or defects remain. Items failing to meet standards are separated and reprocessed to maintain uniform quality.

Fabrics are then packed in specialized bags or wrapping materials to isolate them from dust and bacteria during transport completely. Packaging is designed to maintain absolute hygiene, ensuring products reach the customer in pristine condition.

With this strict inspection and packaging process, Green Laundry guarantees laundry products that meet the highest standards and are ready for immediate partner use.

9. Delivering

After inspection and packaging, all laundry is transported using Green Laundry’s dedicated vehicles. Each shipment follows a fixed delivery route with documented handover records to ensure safety during transportation.

With this delivery service, Green Laundry provides a high-quality laundry solution and absolute reliability and on-time performance to all partners.

The 9-step process at Green Laundry ensures superior cleanliness while complying with hygiene, disinfection, and safety standards. This is a key factor enabling us to meet the laundry demands of hospitals, hotels, factories, and professional service facilities.

Green Laundry – the leading company in providing quality and professional laundry solutions in Vietnam

Email: greenlaundry@giatuixanh.com

Phone: 028 36 222 180

Address: Lot A57/II-Lot 58/II, Road No. 2D, Vinh Loc Industrial Park, Binh Tan Ward, Ho Chi Minh City.